Bestomech started its operation in 1991 , with a conventional setup to cater the needs of the local air compressor and textile pulley market ,eventually growing into the leading

manufacturer of pulleys ,

sheaves

andmachined components

with in-house manufacturing setup from Cast iron foundry, machine shop to CED coating plant. Our main goal is provide total solution for all of our customer needs . By forward and backward integration we have established as a distinguished pulley manufacturer in India.We specialize in

precision manufacturing of pulleys,

sprockets,

timing pulleys ,

elevator traction parts, housings ,machined components and Power Take Off(PTO) drive rings in a shorter lead time.By adopting Lean techniques, 5’S, Cell Concept practices, industry 4.0,TPM , Bestomech has ushered in to the era of objective changes in superior modes of production, Quality & on time delivery.

Continuous investments in new technology, combined with a constant updation of the machine tools for maximum efficiency, allow us to maintain the highest quality standards in the sector, while guaranteeing the optimization of production processes at the same time.

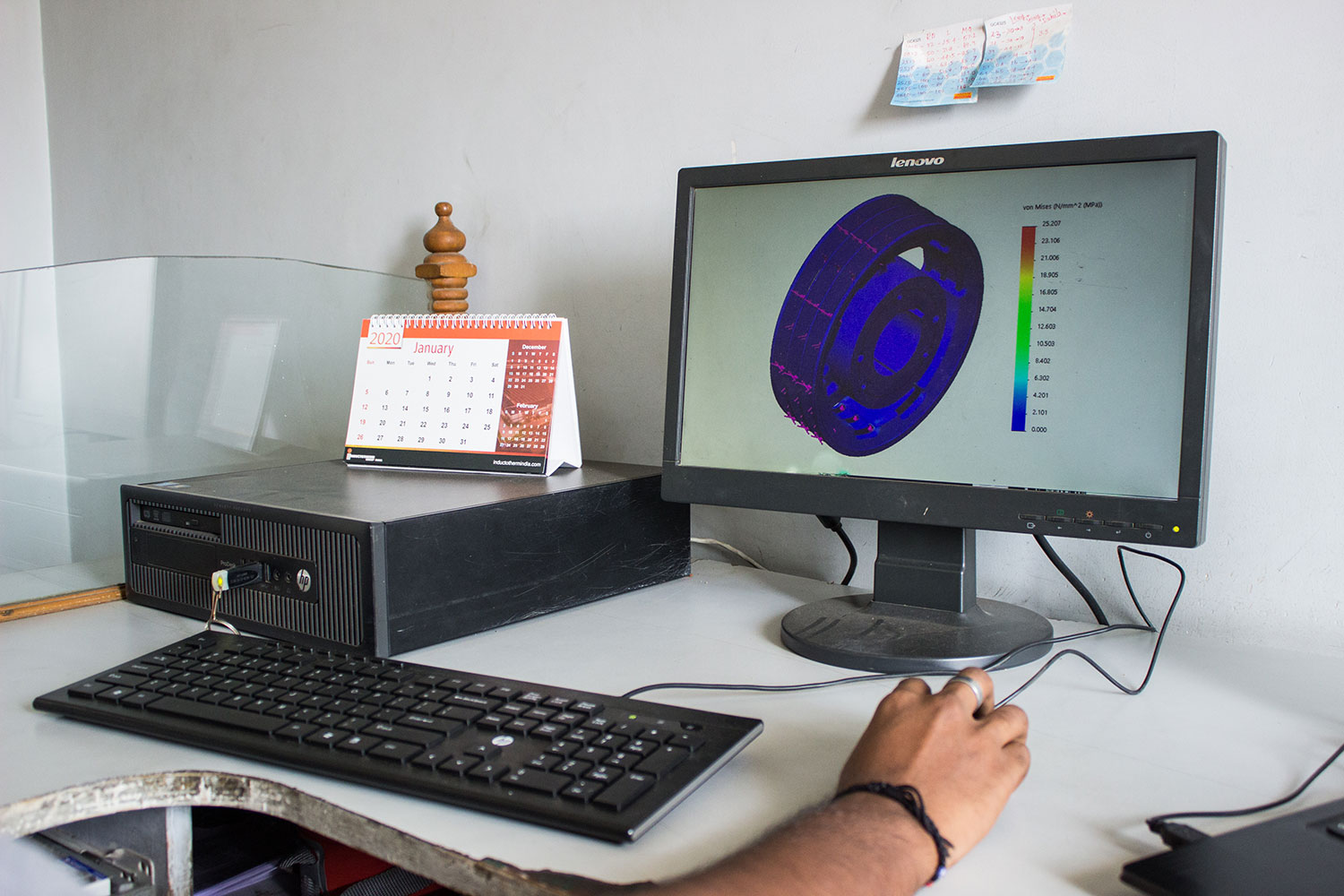

Design

We have a dedicated design department working towards continuous improvements and constant re-engineering of pulley designs. Bestomech being a client centric organization, we also design pulleys and other machined components for customer’s specialized requirement.

Designs are optimized for maximum efficiency by strength analysis , casting and machining simulations to ensure fail proof design and methodology.

Foundry

Bestomech is equipped with DISAMATIC foundry and induction furnace with contemporary manufacturing facility. All our foundry process are thoroughly controlled.